DO NOT MISS OUT! AMAZING THINGS ARE COMING!

Systemise your Business, streamline your operations, reclaim your time.

Let us help you turn your business into an asset with functionality and finesse so you can step back, scale or sell seamlessly.

How do you grow a successful company if growth brings inefficiencies, overwhelm and burnout?

You've built a business with passion and purpose and it's scaling quickly.

You wanted a business that gave you freedom. But right now you're working non-stop. Everything lives in your head. Nothing moves forward without your input and it's draining your time and increasing your mental load.

Entrepreneurs admit that growing revenues are often accompanied by increased admin, more responsibilities and less time freedom.

What would change if you could implement strategies that helped you escape your to-do list? Allowed you to take a month-long vacation? To hire more people? Or focus solely on growth and strategy?

Benefits

Implementing systems that streamline operations is the BEST way to scale your company efficiently to increase profits, decrease expenses and reduce your workload.

Here are a few more of the benefits that these business systems will bring.

WORK WITH ME

Move from overwhelm to streamlined success

Business Systemisation

Transform your business operations in 90 days.

This service streamlines your workflows, ensuring you have systems to support growth and innovation.

We begin by understanding your goals and reviewing your current systems in key areas such as Sales, Finance, Inventory Management and Administration.

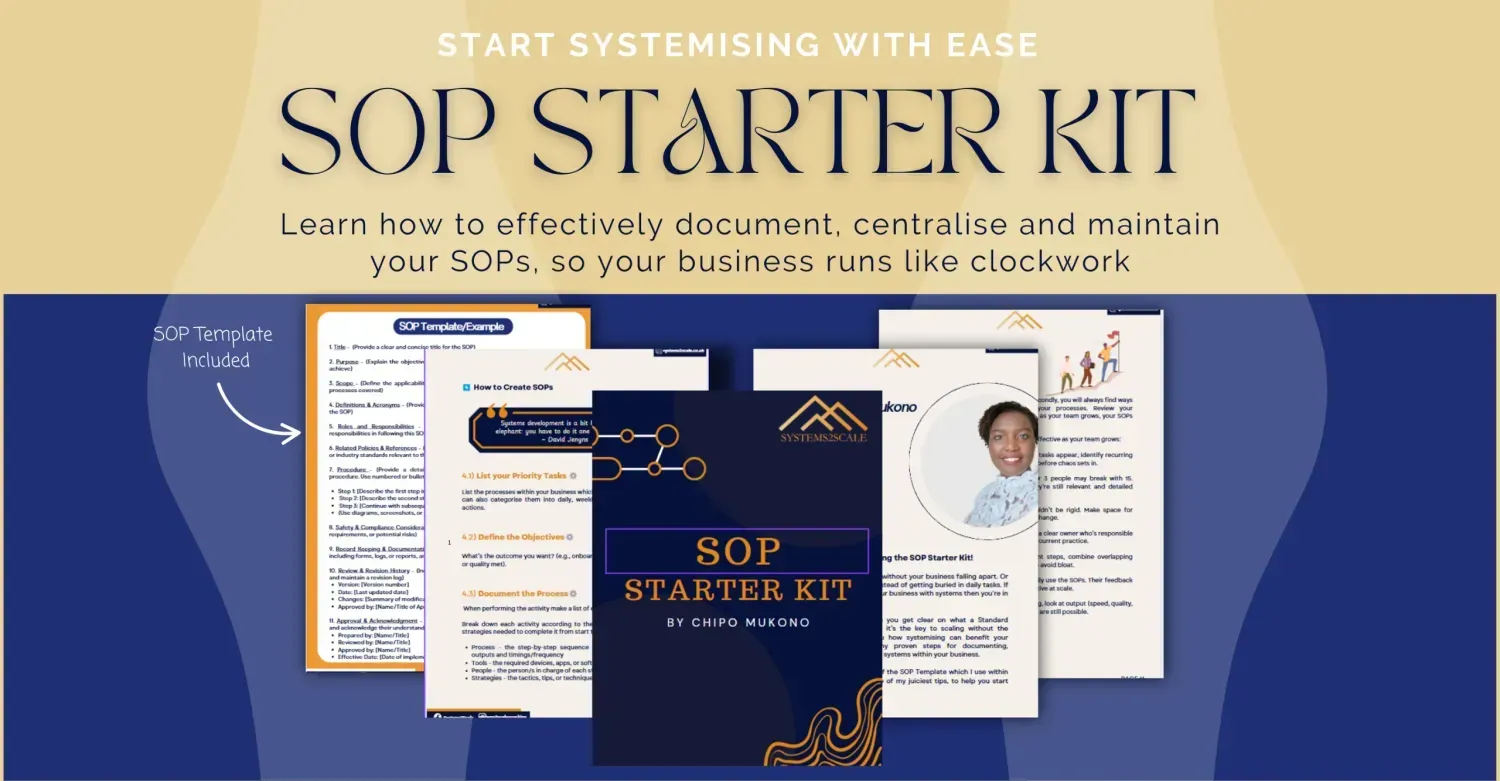

Then, we develop detailed Standard Operating Procedures (SOPs) that provide a clear roadmap for your team.

Finally, we train you and your team to seamlessly access, use, and maintain these systems.

Business Coaching

One-to-one Coaching allows us come alongside you to provide the training, expertise and encouragement to scale your business.

Benefit from monthly strategic planning sessions and project management services to navigate growth opportunities and challenges.

Unlock your business’s full potential with comprehensive support and strategic planning, for long-term success!

With continuous support, you'll be equipped to meet your goals and drive sustained growth.

Contact us to find out more.

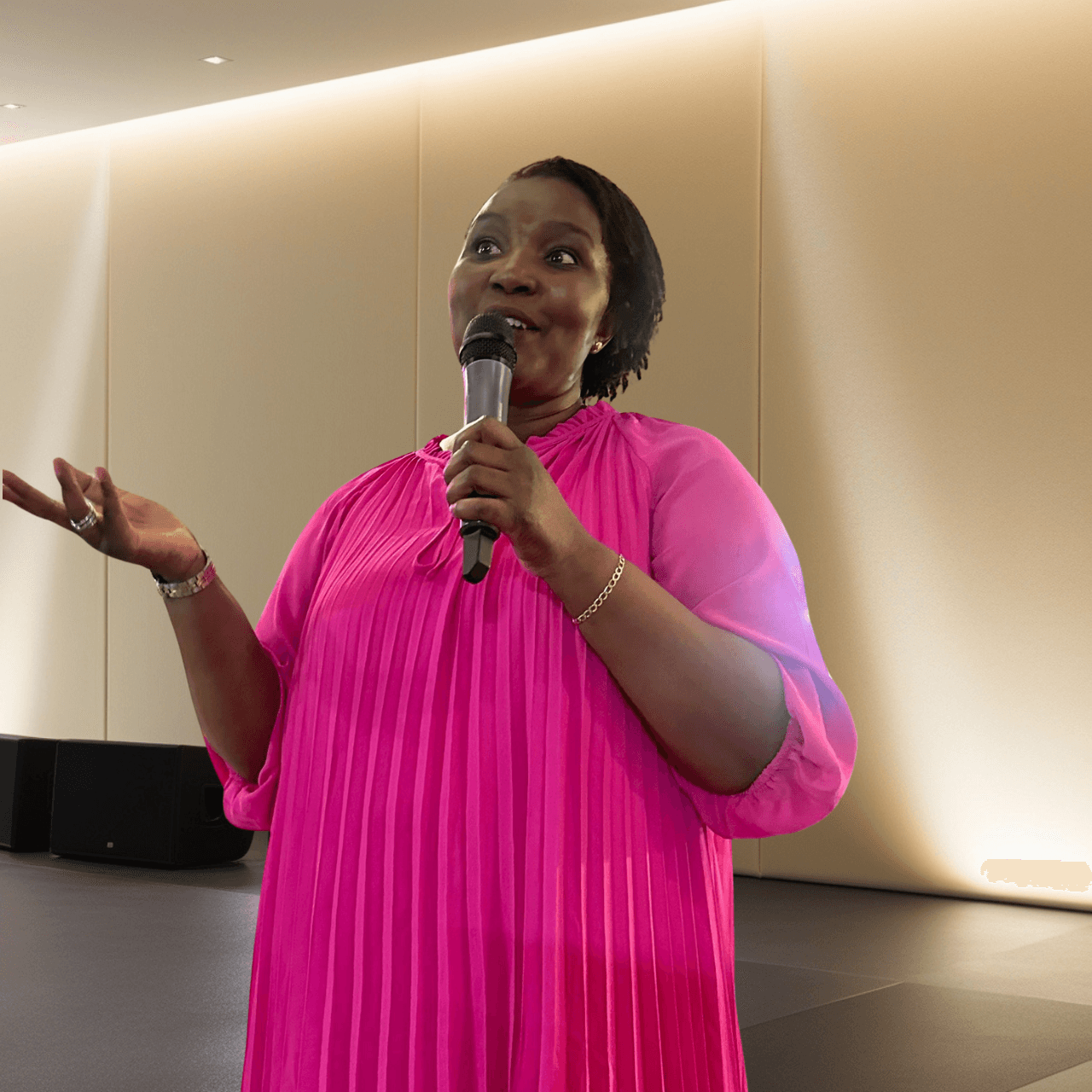

NICE TO MEET YOU

I'm Chipo Mukono

A seasoned business coach with over 20 years of experience, I combine an engineering background, an MBA, and management consulting expertise to drive business growth.

My goal is to empower entrepreneurs to navigate the challenges of building thriving businesses - through shared community, training and coaching.

And to share the encouragement, learning and tools, resources that will help them to scale their businesses and flourish.

TESTIMONIALS

With 20+ years in business strategy and operations, I help ambitious business owners get out of the day-to-day grind and into effortless leadership.

Here's what others say...

Chipo is Amazing. I have worked with her for a year and the relationship is invaluable. If you have the opportunity to work with her I cant give her a high enough recommendation. She is a top level pro and really knows her stuff.

- Nathan Bailey

Chipo's coaching has been brilliant. She's held me accountable, been transparent, supportive and knowledgeable. My business turnover has doubled since I started working with her.

- Aqeeb Chandra

Working with Chipo has transformed my business. I now have a trained team, more time to myself and feel in control of all aspects of the operations.

- Cathy Marino

LATEST FROM THE BLOG

Level Up your Business Skills

Subscribe for the latest tips, trends, and best practices for growing your business.

January 22, 2026

January 15, 2026

January 6, 2026

December 20, 2025

Are you ready for your business to run without you?

If you have been feeling like your business will crumble the minute you step away, then the ultimate guide in building a business that can run without you is here for you.

© 2026 Systems2Scale Home

Where I’m speaking soon

Federation of Small Businesses

Women in Business National Networking

11/03/2026, 10:00 AM

Join us Fridays at 13:00pm for The Growth Table - a live session for SME business owners ready to scale.

We cover systems that boost efficiency, smart delegation, and mindset shifts that support sustainable growth.

Get real insights, real strategies, and space to ask your biggest questions.